Loading Dock Approach Grade is Critical

Loading Dock Approach Considerations

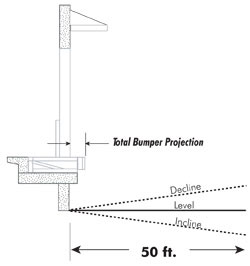

The loading dock approach can be a level approach (level grade apron), decline approach (decline grade apron towards the building) or an inclined approach (inclined grade apron towards the building).

Level Dock Approach

The best approach is a slight inclined approach that allows water to run-off away from the building, this also diverts water run-off from the top of the trailer and away from the dock door which helps prevent water damage to products at the loading dock. Also a slight incline approach aids trailer placement, i.e. the nose of the truck is raised, tilting the back of the trailer closer to the dock, before the trailers landing gear lowered, it puts less force on the building wall, thus less chance of damage to the building.

Best practice is to have a minimum of 6″ bumper project on a level grade, please review dock bumper section for proper bumper projection (note: raising the nose of the truck to drop a trailer changes the dock grade and the dock bumper projection must be able to accommodate this change).

Loading Dock Planning

- Loading Dock Design

- Loading Dock Safety

- Loading Dock Apron Space

- Loading Dock Truck Bays

- Loading Dock Types

- Loading Dock Approach

- Loading Dock Truck Types

- Loading Dock Height

- Loading Dock Door Sizes

- Dock Seal & Dock Shelter Selection Criteria

- Dock Seal & Shelter Selection Guide

- Selecting Dock Leveler Capacity

- Selecting Dock Leveler Size

- Selecting Loading Dock Bumpers

Level Dock Approach

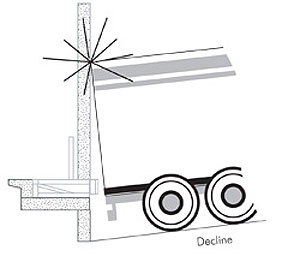

Decline / Incline Dock Approach two problems exist for decline docks, which needs carefully planning. First, a decline dock must protect the truck top from hitting and damaging the building wall, please review dock bumper section for proper bumper projection (note: when raising the nose of the truck it changes decline/incline grade when dropping a trailer and the dock bumper projection must be able to accommodate this change in decline/incline).

The same is true on an incline, however instead of the top of the truck, it’s the bottom of the ICC bar that may hit and damage the dock face. Second, if the decline/incline is severe, loads may topple, loading/unloading becomes difficult and can place greater wear and tear on material handling equipment, also if using a hand pallet jack it may become unsafe to use this equipment to load/unload product.

It’s also a good point to realize that if a dock does not have proper bumper projection, it not only damages the building, it could lead to the building wall failure, which could cause injury or death to the people inside, on the loading dock.

A decline / incline dock approach grade should never exceed 10%.

Determine Dock Approach Grade

The required dock bumper projection is determined based on the percentage of grade. To calculate the grade, measure the difference in height from dock level to a fixed point 50′ directly out from the dock. Divide the height by the length measured, using inches (e.g. 18″ difference over 600″ distance. 18/600 = 3% grade).

FIND THE RIGHT DOCK SEAL/SHELTER

At Chalfant finding the right dock enclosure for your application just got easier. Whether its a dock seal, hybrid dock seal, flexible dock shelter, rigid dock shelter or or rail shelter, we can help guide you in making the right selection for your application.

SELECT A TOUGH DOCK LEVELER

Chalfant dock levelers and edge-of-docks are made of tough diamond tread plate design that assures a non-slip surface for greater safety and stops that lock the board firmly in place, for easy loading. Find out which “tough dock leveler” is the right choice for your application.

CHOOSE THE BEST TRUCK RESTRAINT

At Chalfant finding the right dock enclosure for your application just got easier. Whether its a dock seal, hybrid dock seal, flexible dock shelter, rigid dock shelter or or rail shelter, we can help guide you in making the right selection for your application.

Proper Loading Dock Equipment Selection

Contact us today for help you with proper loading dock equipment selection for your loading dock equipment application. We can help you in properly select and specify dock seals, dock shelters, rail shelters, dock levelers; hydraulic dock levelers and mechanical dock levelers, truck restraints, and your loading dock equipment needs, to meet your unique needs.